2023-02-21

2023-02-21

At present, the production of annealed wire and steel wire generally adopts wire drawing process and galvanizing treatment. In 1976, Guangzhou Galvanized Iron Wire Factory first applied the new technology of electrolytic pickling, high pressure washing and electric drying in China to successfully test the continuous production of the wire drawing line, which made the wire drawing process change from intermittent production to continuous production, reducing labor intensity and metal consumption. At that time, the domestic wire factory has been able to produce steel wire rope, spoke steel wire, umbrella steel wire, spring steel wire, bicycle saddle spring steel wire and other products. In the 1980s, hot-dipped low-carbon steel wire for stapling, fan mesh steel wire, carbon structural steel wire, bed surface, steel wire, etc. also came out one after another.

In the formal field, the role of black iron wire is too broad. We can use black iron wire to bind items that need to be bound, or use it as a sealing strip for sacks. For example, if we want to put something into the fire and burn it, but we are afraid that it will spread, we can use black iron wire to bind it. The heat resistance of black iron wire is very high. As long as the black iron wire is extended, it can be taken out again by using the hook of the black iron wire after the object is burned and smelted. It is very reliable.

Black iron wire is a kind of metal wire made of low carbon steel. Black iron wire has different components according to different uses. It contains components: iron, cobalt, nickel, copper, pore size, and performs cooling, annealing and coating of different specifications of black iron wire.

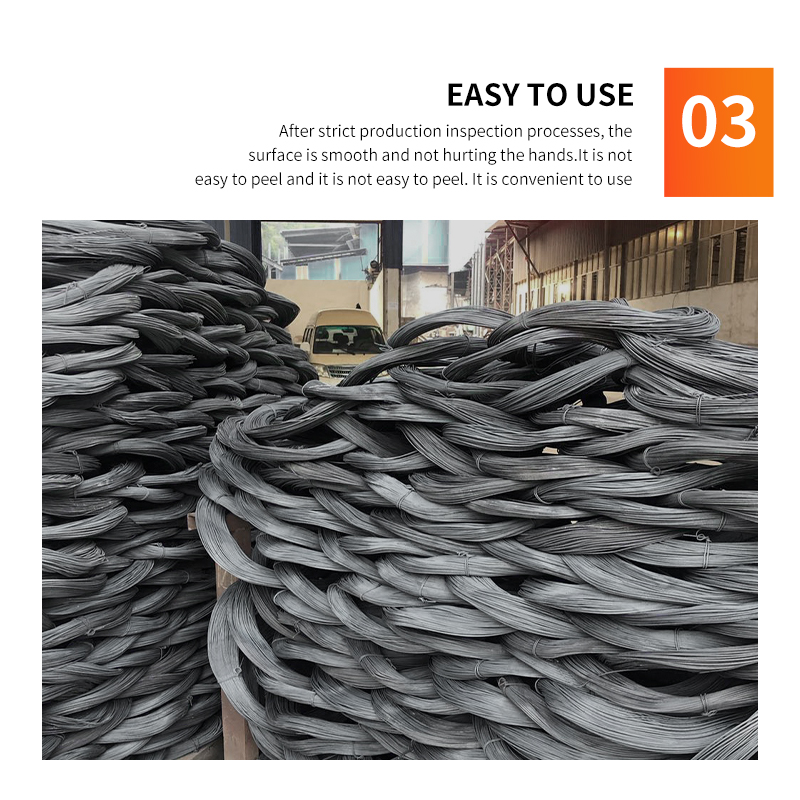

Features: It is softer and more flexible than ordinary black iron wire, with uniform softness and color.

Usage: mainly used in construction, mining, chemical industry, welding mesh, welding clothes rack, reprocessing, etc. After annealing, the iron wire becomes soft, the flexibility increases, and the effect of building wire binding and rebar binding is better.

Eshan Jinfeng Metal Products Co., Ltd. is a company specializing in the production of galvanized iron wire production lines; the project was reported to the Eshan County Economic Commission for review on April 27, 2007, and the project was in line with the national industrial policy; May 9, 2007 Reported to the Eshan County Construction Bureau for approval, the project It meets the requirements of the county's enterprise planning and site selection; the company is a private enterprise, and its operation mode is an independent legal entity that is responsible for its own profits and losses and independent accounting. The company covers an area of 8,000 square meters, with a total project investment of 32 million yuan, including 8 million yuan for civil construction, 22 million yuan for equipment, and 2 million yuan for environmental protection. There are more than 100 employees, including 20 managers, 8 senior technicians, 7 intermediate technicians, and 11 junior technicians, with an annual output of 30,000 tons.

The company's raw materials are made of high-quality Q195 special steel for wire drawing, combined with cold drawing, annealing, sulfate galvanizing, and have the characteristics of anti-corrosion, anti-rust, softness, etc. It sells well all over the country and in international markets such as Myanmar and Laos. Since August 2014, the company has obtained the right to export and has earned more than 31 million yuan in foreign exchange.

Ma Jianxi

13608868862@139.com