2022-11-15

2022-11-15

Chengdu Extrusion Mold Machinery and Equipment

(1) General plastic machine (with slightly higher precision).

(2) N2 automatic control system, including self sealing gas auxiliary nozzle.

(3) High pressure nitrogen generator.

(4) Increase industrial production of nitrogen cylinders and air compressors.

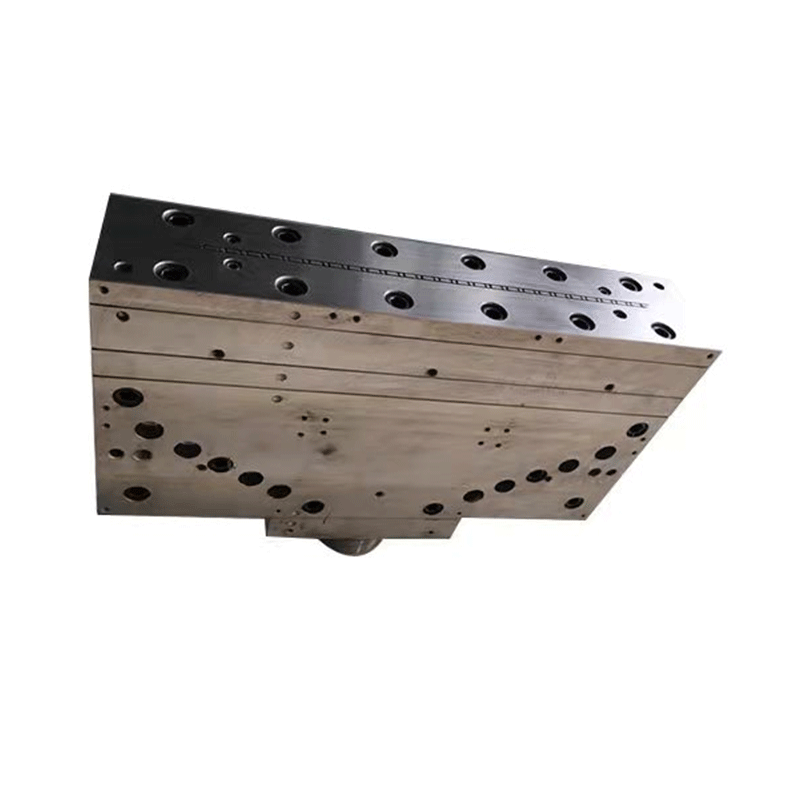

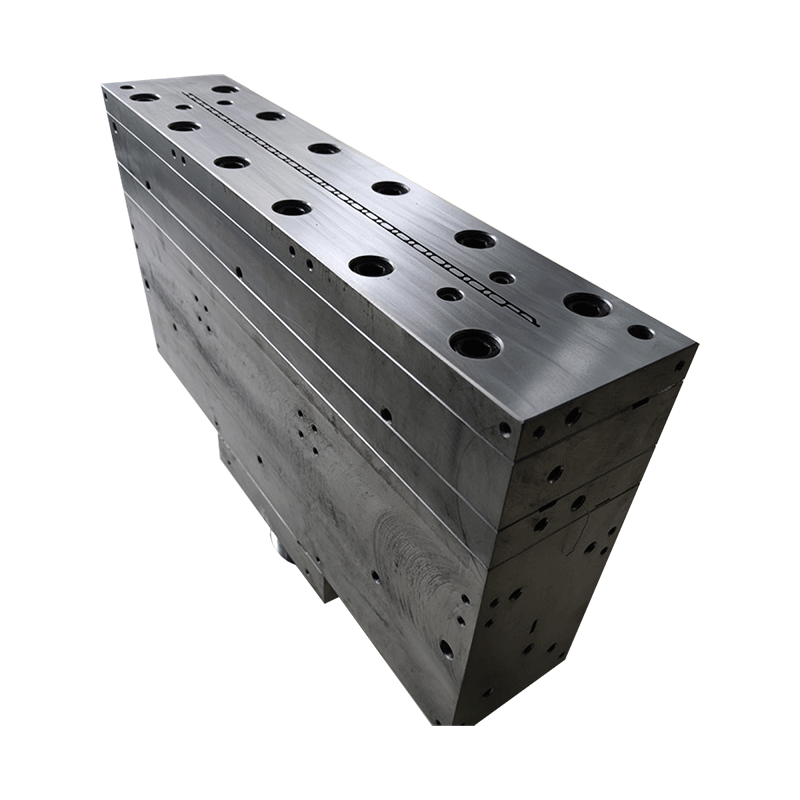

(5) Design and manufacture of moulds for gas assisted injection.

(6) Laminated nozzle of extrusion die:

The air inlet method of the nozzle is to select a unique self enclosed gas auxiliary nozzle. After the injection of plastic, high pressure gas directly enters the plastic according to the nozzle, and a widened closed gas chamber is generated according to the gas pipe, and a certain working pressure is maintained until it is cooled. Before opening the mold, according to the backward movement of the base, the nozzle and the raw material safety channel of the commodity are forcibly separated, and then the gas is discharged from the commodity.

(7) Air needle:

The air inlet method of the air needle is to install the air water separator - air needle in the special part of the mold. After the plastic is introduced into the inner cavity, the air needle is wrapped inside the plastic; At this time, the high pressure gas is discharged, and the air needle generates a widened closed air chamber in the plastic according to the basic principle of the air pipe, and maintains a certain working pressure until refrigeration. Before the mold is opened, the gas in the gas chamber is discharged from the plastic by the operating device according to the air needle.

Wallboard mold: mold used to produce decoration wallboards. The wallboard mold has high requirements on the appearance and overall dimension accuracy. The appearance is smooth and flat, without looseness, honeycomb, etc. The wallboard mold must have a certain stiffness and strength, and a strong overall stability.

During processing, Zoje extrusion dies usually add powder or granular polymer to the extruder barrel. Under the action of screw or plunger, the polymer moves forward along the screw groove or cylinder and gradually melts into viscous fluid. Then, through the mold set at the end of the cylinder, a continuum similar to the shape of the die mouth is formed. Finally, after cooling and molding, products with required shapes can be formed, such as various plastic pipe rods, sheets, plastic steel doors and windows, films, decorative skirting lines, etc. The general design points of the extrusion die are the core of extrusion production.

Chengdu Weishui Machinery Equipment Co., Ltd. is a professional company integrating mold technology research and development and manufacturing. The company was founded in early 2007, and is located in the south area of industrial concentrated development in Qingbaijiang District, Chengdu. The company has introduced several production equipment. Including machining centers, slow wire walking, CNC EDM, CNC wire cutting, lathes, milling machines, etc., to ensure the precision and service life of products. "Siyou Mold" has become the leader of extrusion mold brands in Southwest China.

Ma Pingquan

yf2190276763@gmail.com